Dewatering Screen Panels

2020-08-04

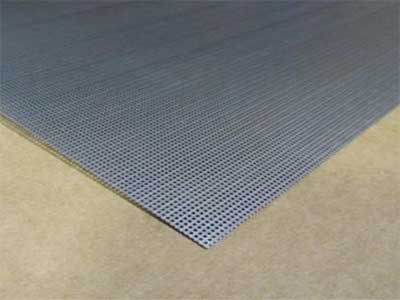

Dewatering screen is mainly composed of a sieve box, vibration motor, sieve plate, elastic support device, etc. Each component plays an important role in the process of dehydration and desliming. The sieve panel is divided into stainless steel welded sieve panel and polyurethane sieve panel.

Many customers in the purchase of dehydrated screen, it is easy to ignore the screen plate. The screen plate is a consumable when it’s working, and regular replacement of the screen plate is one of the daily maintenance of the dehydrating screen.

General dehydrating screens are used in the polyurethane screen panels, this material is now the mainstream choice in the market. So how to choose a good quality polyurethane dehydrating sieve panel?

1. Look at the appearance of the polyurethane screen

See whether the screen surface is fine, whether the screen is flat, whether the color is pure, whether there is a burr, lack of material, mixed materials and other phenomena.

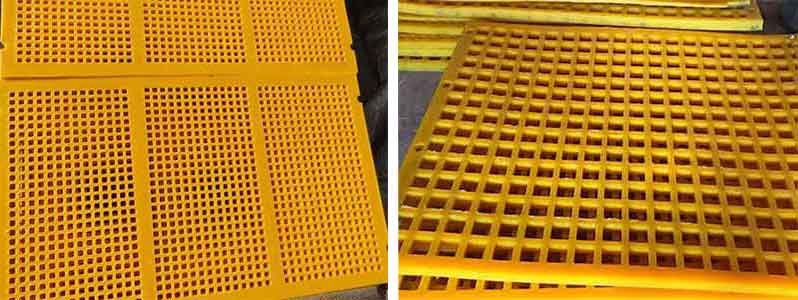

2. Look at the opening rate of the product

The opening rate is the most direct factor affecting screening efficiency. The more holes the polyurethane screen pieces have, the higher the screening efficiency and yield will be.

3. Look at product connections

The connection mode of the polyurethane screen has a direct impact on the screening efficiency, which ensures the tight connection between the screens and no ore leakage.

4. See if the mesh is even

High-quality polyurethane screen with uniform and standard holes and small tolerance range.

5. See if the hardness and softness are moderate

High-quality polyurethane screen to rigid and moderate, in the actual production of polyurethane screen to have strong flexibility, in order to ensure that the production does not collapse, but also to have a certain toughness, to ensure that the screen is not easily broken.