Dewatering screen with hydrocyclone in waste water treatment process

2020-08-01

The dewatering screen with hydrocyclone is a fine sand recovery machine, which is designed to deal with sand with small particles and easy to be lost.

The hydrocyclone is also called hydraulic separators, a kind of common separation and classification equipment, which is not necessary to install in ordinary dewatering operation. It could select the material to be treated according to the specific conditions.

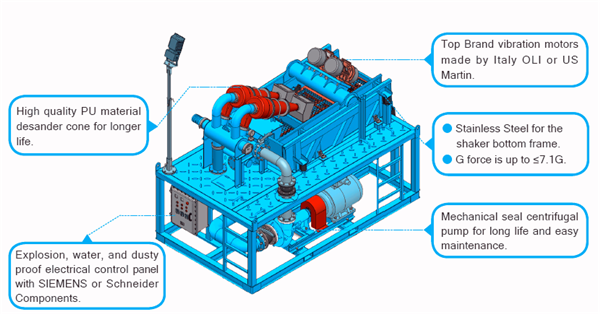

Dewatering screen with hydrocyclone

Why install a hydrocyclone?

In case of need to deal with tailings dry line, the hydrocyclone on the dewatering screen not only can be used in a variety of mineral slurry dewatering, but it also disposes of sewage according to the different material properties of tailings, different production installation environment, different structural design, so has the advantages of large quantity, high dewatering efficiency, so it is the ideal equipment for dewatering in sewage treatment.

How does fine sand recovery machine work?

The dewatering screen with hydrocyclone is mainly composed of motor, vacuum high-pressure pump, sediment separator, TS dewatering screen, cleaning tank and return box.

The mixture of pumping sand and water is transferred to the high-pressure separator. The centrifugally graded concentrated fine sand is provided to the dewatering sieve through the grit mouth. After dewatering through the dewatering sieve, fine sand and water are separated effectively. A small amount of fine sand and mud return to the cleaning tank. When the liquid level of the cleaning tank is too high, it will be discharged through the outlet. The weight concentration of the recovered material of the dewatering sieve is 70%-85%. The adjustment of fineness modulus can be achieved by changing the pump speed and mortar concentration, adjusting the amount of overflow and replacing the mortar nozzle to complete the cleaning, dehydration and classification of the three functions.

Advantages

1. Integrated with cleaning, recovery, dehydration and other functions, it can effectively extract the fine particles lost in tail water, so as to improve the utilization rate of mineral resources.

2. Unique involute and spiral curve combination design is adopted inside the cyclone. The inner lining is made of high-quality polyurethane material with good wear resistance.

3. The vibration damping element of the equipment is high-quality rubber spring with good elasticity, large damping and not easy to aging.

4. The equipment is equipped with a return water tank, return water regulating valve and feeding ports on both sides. The overall structure is compact, covers a small area, and can meet the needs of different sites with good universality.