How To Install A Vibrating Screen

2020-07-18

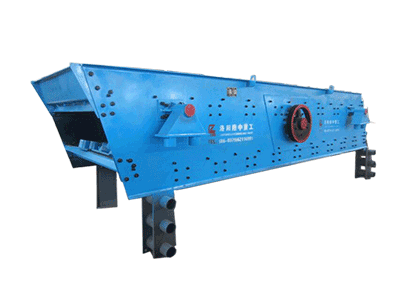

Vibrating screen is a kind of filter mechanical separator,which is used for classification, washing and dehydration of materials.It is widely used in mining, building materials, energy and other industries.This article shares how to install the vibrating screen and installation debugging matters needing attention.

Preparation before installation

Before the installation, it is necessary to carefully check the factory material of the vibrating screen to see whether it conforms to the national standard.Check for rusty parts, and replace aging seals.Carefully read the installation instructions.

Installation procedure

(1) Install the supporting or hanging device

The installation ground must be flat and the spring components should be on the end of the actual stiffness of the mark for matching.

(2) Connect the screen box to the supporting or hanging device

After installation, it should be adjusted according to the specified inclination.Hanging screen should be adjusted at the same time the screen box Angle and spindle level.

(3) Install the motor and triangle tape

During the installation, the foundation of the motor shall be leveled and the motor shall be calibrated horizontally. The center lines of the corresponding grooves of the two rubber belts shall coincide. The tension of the triangular rubber belt shall be appropriate.

(4) Install as required and fix screen surface

Notes for trial operation

(1)In the span of eight hours, observe whether the sieve starts smoothly and rapidly, whether the vibration is stable, and whether there is any special noise.

(2)When the sieve is running, the vibration of the sieve box shouldn’t produce a horizontal pendulum.

(3)The highest temperature of bearings shouldn’t exceed 75℃, and the temperature rise shouldn’t exceed 40℃.

(4)If abnormal noise or bearing temperature rises sharply after starting the machine, stop the machine immediately.