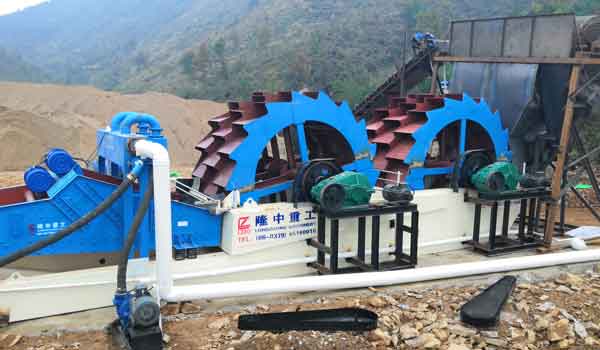

Sand production line equipment configuration

2022-04-29

The investment scale is the main factor affecting the overall investment cost of the sand production line. The investment cost of a large sand production line is relatively high, usually in the millions, but the specific investment cost depends on the scale and equipment configuration of the sand production line. To invest in a sand production line, to save investment costs. Considering multiple factors, the following will introduce to you how to invest in a sand production line to save money?

1. Do a good job of investment budget and planning

Investing in sand-making production projects should not be done blindly. Investment planning should be done well, including the acquisition of raw materials, the handling of sand-making procedures, the leasing of sand-making sites, equipment procurement and post-maintenance, as well as labor costs, water and electricity costs, etc. All need to be considered. Investing in manufactured sand projects involves a lot of costs. Without adequate planning and budgeting, it is difficult to control the cost of each link.

2. Understand the characteristics of raw materials and choose suitable equipment

To understand the characteristics of the raw materials of artificial sand, including hardness, particle size, water content, etc., the raw materials with different characteristics have different crushing and sand-making equipment, so it is necessary to choose the appropriate sand-making equipment according to the characteristics.

For example, when crushing pebbles, yellow granite, basalt, and other materials with high hardness, it is necessary to choose cone crusher equipment with high wear resistance, and crushing materials with moderate hardness such as limestone, coal, white cloud, etc. It can ensure the grain shape of sand and gravel, and will not cause waste of energy consumption.

3. Choose a reliable manufacturer

To save investment costs, in addition to paying attention to the price of sand-making equipment, it also depends on the later operation of the equipment and the after-sales service of the manufacturer. After a long period of operation, sand production equipment is prone to failure in the later stage, and the overhaul and maintenance costs of the equipment are not small expenses. Strong and large-scale sand-making equipment manufacturers can not only guarantee the quality of the equipment but also provide users with comprehensive after-sales service promptly, saving users maintenance costs. Therefore, to save the cost of sand making, it is necessary to choose a sand-making equipment manufacturer with strong strength, large scale, and rich experience.

The above introduces how to invest in the sand-making production line to save money from three aspects. The investment in the sand-making production line is not a small expense. Therefore, a reasonable investment can help users reduce economic pressure and improve the sand-making production line. production effect.