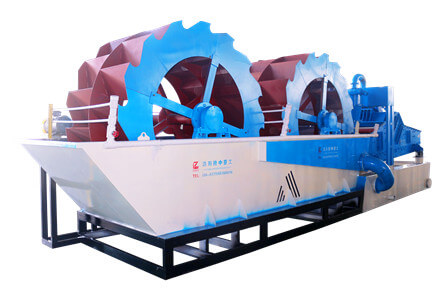

Dual Wheel Sand Washing Plant:

Dual Wheel Sand Washing Plant integrates two set wheel sand washing machines with the dewatering screen and hydrocyclone separator, which is specially designed for washing, grading, recycling, and concentrated dewatering of coarse and fine materials.

Dual wheel sand washing plant can widely process sandstone and quartz sand, aggregate, coal, ore, tailing, etc.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

Dual Wheel Sand Washing Plant is a new type of sand washing machine. On the basis of our original sand washing equipment, the equipment has been updated and upgraded to meet the needs of customers. The dual wheel sand washing plant is skillful in docking two wheel bucket washing machines with fine sand recovery machines.

The whole machine has a reasonable structure and small area, which greatly reduces the investment cost for customers in the sand washing link. It integrates heavy water washing and fine sand dehydration and recycling.

Working principle

After the pre-processed material enters the first storage tank, the first washing wheel starts to rotate through the motor and reducer, and the material in the first storage tank is picked up from the water and passed through the mesh in the washing wheel. The water and the material below the mesh size are missing, and the qualified material is transferred to the second storage tank. During the rotation of the washing wheel, the material is in full contact with the water, and water is used to remove the impurities on the surface of the material. so the material is cleaner.

The second washing wheel repeats the process of the first washing wheel, and the material is cleaned again.

Then the material enters the dewatering device and removes a lot of moisture through the vibrating screen, which makes the material more convenient to store and transport.

Features

- 1.Two sets of wheel sand washer , water storage tank, pumping tank, water reverse device, overflow device, separation and recovery device, dewatering device, reducer, pump, motor and other components.

- 2.The structure is reasonable and the output is stable.

Dual Wheel Sand Washing Plant Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| 2DL40 | ≤10 | 20-40 | 1800*800 | 250*2 | 1200*2400 | 32.4 | 7120*3650*2160 |

| 2DL60 | ≤10 | 30-60 | 2600*1200 | 300*2 | 1500*3000 | 44 | 8900*5560*2750 |

| 2DL80 | ≤10 | 40-80 | 3000*1600 | 300*2 | 1800*4200 | 52 | 11600*5860*3370 |

| 2DL100 | ≤10 | 60-100 | 3000*1600 | 350*2 | 1800*4200 | 63 | 11600*5860*3370 |

| 2DL150 | ≤10 | 100-150 | 3600*2000 | 300*4 | 2400*4200 | 97 | 12800*6560*3970 |

| 2DL200 | ≤10 | 120-200 | 3600*2400 | 350*4 | 3000*4800 | 126 | 12800*7150*4170 |

| 2DL250 | ≤10 | 160-250 | 4200*3000 | 300*6 | 3600*6000 | 164 | 14400*7740*4860 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.