Spiral Sand Washing Plant:

Spiral sand washing plant is a multi-functional sand washing equipment that integrates sand washing, dewatering and recycling, which is designed and developed by our company for sand, stone powder, and other materials with high mud content in sand and gravel washing industry.

The reasonable structure of dewatering screen combined with sand screw washer to form an overall structure, which can reach more than 300 tons per hour.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

Spiral Sand Washing Plant is a high efficient and multi-functional water washing equipment, which is composed of a spiral sand washing machine and a dewatering screen and hydrocyclones. Compared to the purchase price of equipment alone, the choice of spiral sand washing machine is undoubtedly more cost-effective.

The spiral sand washing plant consists of spiral sand washing device, overflow device, water reverse device, separation and recovery device, water storage tank, slurry pump, elrctro motor, reducer and so on.

Working Principle

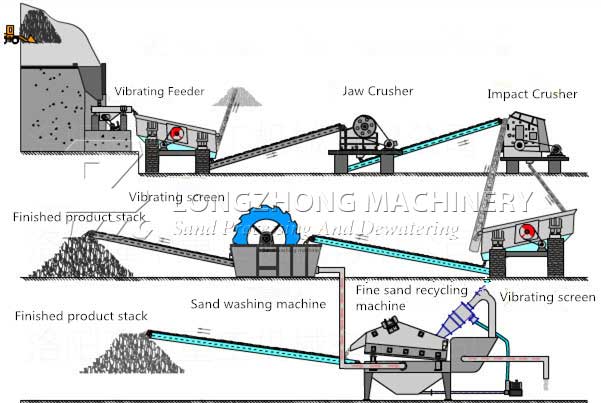

When the spiral sand washing plant is working, the crushing and grading materials are first passed through the conveyor belt to the double spiral sand washing device. After the grading and cleaning, the qualified material is dehydrated into the dewatering device, and the remaining waste water that after cleaning by the spiral sand washing device (containing a part of qualified material) is passed through the overflow device and get into the water reservoir device, then the waste water is pumped into the separation recovery device by slurry pump, material is concentrated under the action of centrifugal force, and the concentrated material get into the dehydrating device for dewatering.

Features

- 1. Compact structure, space saving.

- 2. The production range is large and can be customized.

- 3. High efficiency, more economical and practical.

Spiral Sand Washing Plant Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Hydrocyclone (mm) | Screen Panel(mm) | Power (kw) | Overall Size (mm) |

| LY40 | ≤10 | 20-40 | 760 | 250X2 | 1200X2400 | 37.4 | 10880X5240X3720 |

| LY60 | ≤10 | 30-60 | 920 | 300X2 | 1500X3000 | 51 | 11490X5560X3960 |

| LY80 | ≤10 | 40-80 | 1120 | 300X2 | 1800X4200 | 59.5 | 12830X5860X4250 |

| 2LY100 | ≤10 | 60-100 | 920X2 | 350X2 | 1800X4200 | 82 | 12630X5850X3860 |

| 2LY150 | ≤10 | 100-150 | 1120X2 | 300X4 | 2400X4200 | 97 | 12630X6450X4150 |

| 2LY160 | ≤10 | 100-160 | 1120X2 | 350X4 | 3000X4800 | 141 | 13560X7860X4300 |

| 2LY200 | ≤10 | 100-160 | 1120X2 | 350X4 | 3000X6000 | 148 | 14760X7860X4300 |

| 2LY250 | ≤10 | 160-250 | 1500X2 | 300X6 | 3600X6000 | 178 | 14760X7920X4900 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.