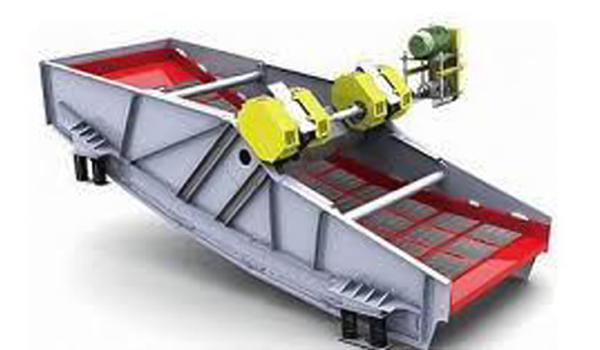

Banana screen:

A Banana vibrating screen is defined by its shape, which is called a banana screen for short. It has a box-type vibrator and linear vibrating screen with multiple screen surfaces with different inclination angles. It is mainly used for particle size classification of large and medium-sized materials with high fine particle content, and can also be used for coal or similar minerals with dry and wet sieving and medium and mud removal of coal.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

JR banana screen is suitable for screening, dehydration, medium, desliming, and other operations of coal, gravel aggregate, minerals, and other materials. This series adopts different screening areas, screen seam size, number of screen surface segments, and leaning angle of the screen according to the different uses and processing capacity of the screen. It is divided into single-layer and double-layer products. The working area is 5.7㎡~30.2㎡. There are 20 main specifications and models, which can meet the production needs of various types of mines and coal preparation plants.

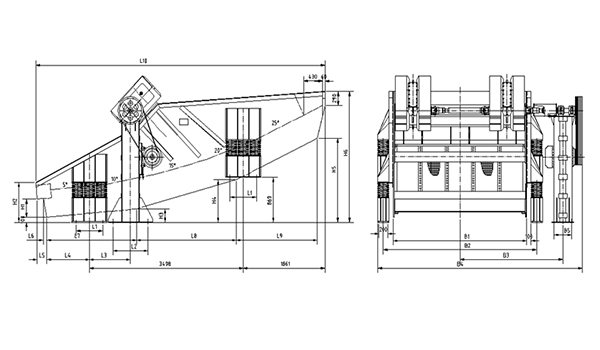

Structure

The Banana vibrating screen is mainly composed of a screen box, screen mesh, vibration exciter, vibration-damping spring, and lower seat frame. It uses a motor and an exciter as the vibration source. The exciter is mainly composed of an eccentric shaft, a pulley, a bearing, and a bearing seat. Connected to it, the motor drives the eccentric shaft to rotate, generating centrifugal inertial force, and forcing the screen box to vibrate.

Technical Characteristics

1. Banana sieve has the characteristics of high screening efficiency and much higher processing capacity than a traditional grading screen and is an advanced screening machine.

2. Vibrator: Adopt the world’s advanced JR type box vibrator, splash lubrication, and built-in lubricating oil channel in the box to ensure full lubrication of the bearing, the gear is a high-precision helical gear, the bearing is a special bearing for vibration equipment, and the oil drain plug With magnetic, external organic plastic transparent oil level, it is very convenient to observe the oil level, special measures are adopted to ensure that the bearings and gears work comfortably, the noise of the vibrator is less than 75 decibels, and the bearing temperature is less than 50 degrees.

3. The beam of the exciter adopts a three-I-shaped beam structure, which overcomes the problem of poor force in the middle of the square beam. It is equipped with reinforcing rib plates, which have high rigidity and lightweight, and can be treated with stress relief after welding.

4. The surface of the beam can be sprayed with a polyurethane protective layer, which is resistant to erosion, abrasion, and long life.

5. The shaped cutting and drilling of the side plate are completed by a high-precision CNC lathe to ensure the accuracy of the shape and drilling. There is no welding seam on the side plate to avoid stress concentration on the side plate, thereby preventing the side plate from cracking.

6. There are two ways to fix the screen surface, one is the middle rail seat type of polyurethane pressed wood at both ends, and the other is the middle-pressure plate type of polyurethane pressed wood at both ends, which can be installed with polyurethane screen surface or stainless steel screen surface. Users can choose according to their needs, which is very flexible.

7. With a feeding box with sufficient strength, rigidity, and length to prevent the impact of large pieces of material or the improper design of the feeding chute, the large pieces of material fall directly into the screen surface, resulting in premature damage to the screen surface.

8. The key components are connected by torsion shear-type high-strength bolts, which are reliable in connection and easy to maintain.

9. The main components are made of Q245R, which is a special steel for pressure vessels, with good impact toughness, cold bendability, and weldability.

10. Each screening machine is tested with no load for 8 hours before leaving the factory to ensure that each screening machine can operate safely and reliably.

11. The steel coil spring is used to reduce vibration to minimize the dynamic load of the screening machine on the foundation.

Banana screen Specifications:

Single-layer

| Model | Layer Qty | Screen size(W*L) (m) | Screen Area(m²) | Segment Qty |

| JR1848 | 1 | 1.8×4.8 | 8.6 | 3 |

| JR1861 | 1 | 1.8×6.1 | 10.8 | 3 |

| JR2448 | 1 | 2.4×4.8 | 11.5 | 3 |

| JR2461 | 1 | 2.4×6.1 | 14.4 | 3 |

| JR2473 | 1 | 2.4×7.3 | 17.2 | 3 |

| JR2485 | 1 | 2.4×8.5 | 20.1 | 3 |

| JR3061 | 1 | 3.0×6.1 | 18 | 3 |

| JR3073 | 1 | 3.0×7.3 | 21.6 | 3 |

| JR3085 | 1 | 3.0×8.5 | 25.2 | 3 |

| JR3661 | 1 | 3.6×6.1 | 21.6 | 3 |

| JR3673 | 1 | 3.6×7.3 | 25.9 | 3 |

Double-layer

| Model | Layer Qty | Screen size(W*L) (m) | Screen Area(m²) | Segment Qty |

| 2JR1861 | 2 | 1.8×6.1 | 10.8 | 3 |

| 2JR2461 | 2 | 2.4×6.1 | 14.4 | 3 |

| 2JR2473 | 2 | 2.4×7.3 | 17.2 | 3 |

| 2JR3061 | 2 | 3.0×6.1 | 18 | 3 |

| 2JR3073 | 2 | 3.0×7.3 | 21.6 | 3 |

| 2JR3661 | 2 | 3.6×6.1 | 21.6 | 3 |

| 2JR3673 | 2 | 3.6×7.3 | 25.9 | 3 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.