Fines Recovery Unit:

At present, the existing artificial sand production lines, large-diameter pile foundations with cyclic drilling technology, non-excavation construction and cut-off wall projects, and tailings sludge in large mining areas are mostly used in wet production processes.

The biggest disadvantage during the process is the serious loss of fine sand, especially the fine sand below 0.16-0.2mm, the loss rate is as high as more than 20%. Not only reduce the production, but also affect the sand grading severely, the fineness modulus increases, and the quality of the product is greatly reduced. Excessive discharge of fine sand not only causes high cleaning costs of the sedimentation tank, but also causes waste of land resources and environmental pollution.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

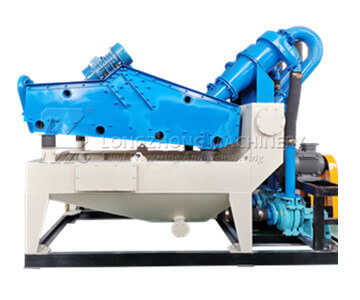

Fines recovery unit is designed for dewatering, de-seeding and de-sliming of slurry materials. LZZG fines recovery unit absorbs advanced foreign technology and combines the actual situation of sand powder to design advanced level of fine materials extraction machine, which can effectively solve the problem of fine sand loss in sand washing plant.

As a new type of environmental protection equipment, fines recovery unit is widely used for the purification of fine sand mud, sand and gravel recovery issues, hydropower systems, glass raw material processing systems, artificial sand production lines and coal preparation plant coarse coal slurry recycling and environmental protection engineering (mud purification).

Working Principle

Wastewater overflowed by sand washing machine is connected to the water tank of fines recovery unit, then sand-water mixture in the cleaning box is pumped into the high-pressure hydrocyclones by slurry pump. Through the high-speed centrifugal force and rated feeding pressure of hydrocyclones the fine sand in slurry is separated.

After centrifugation, the slurry concentration is increased to 60-70%, and then it is sprayed on the screen plates of dewatering screen through the sand nozzle. Under the vibration of the screening machine, dehydration is realized, fine sand is discharged through the discharge port, while a small amount of fine sand, mud, etc. are returned to the cleaning tank through the return tank for the next cycle.

Features

- 1. Reduce the sand erosion, improve the economic benefit at the same time reduces the pollution.

- 2. Vibrating screen using polyurethane screen mesh, and not easy to plug holes.

- 3. Hydrocyclone lining polyurethane, improve the service life of the device.

- 4. Fine sand fully recovery, reduce the workload of settling tank.

- 5. Reduce the stacking time of fine material, can transfer directly to supply the market.

- 6. Whole structure is concise and efficient, easy to operation and maintenance, low operating costs.

Fines Recovery Unit Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| LZ250 | ≤10 | 20-50 | 900*1800 | 250 | 12.5 | 3100*1300*2700 |

| LZ300 | ≤10 | 40-80 | 900*1800 | 300 | 16.5 | 3100*1300*2700 |

| LZ350 | ≤10 | 60-100 | 900*1800 | 350 | 20 | 3100*1300*2700 |

| LZ550 | ≤10 | 40-100 | 1200*2400 | 250*2 | 26.4 | 3600*1600*2800 |

| LZ650 | ≤10 | 80-160 | 1200*2400 | 300*2 | 34.4 | 3600*1600*2800 |

| LZ750 | ≤10 | 120-200 | 1200*2400 | 350*2 | 41.4 | 3600*1600*2800 |

| LZ900 | ≤10 | 120-250 | 1500*3000 | 300*3 | 49.4 | 4600*1900*2600 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.