Screw Sand Washing Machine:

Screw Sand Washing Machine is a kind of efficient sand and gravel washing machine, which is widely used for sand and stone washing, grading and impurities removing.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

Base on years’ experience and technology, LX Screw Sand Washing Machine is designed to provide bigger capacity and higher cleaning level than traditional one. It is also called “stone washing machine” as its input material size is at most 30mm.

Now it is widely used for cleaning materials in quarry, minerals, building materials, transportation, chemical industry, water conservancy and hydropower, cement mixture station and so on.

Working Principle

It is composed of the electric motor, big and small belt pulleys, triangle belt and gear reducer. The sand washer adopts inclination of 15 degree. Under the water tub, three weir plates form the sediment pool. The spiral head is immersed in this pool, and the spiral is driven by electric motor through reducer rotating continuously. The fresh water is feeded from porous plate at bottom of sediment pool, and the washed sand is discharged on the top side and delivered by belt conveyor.

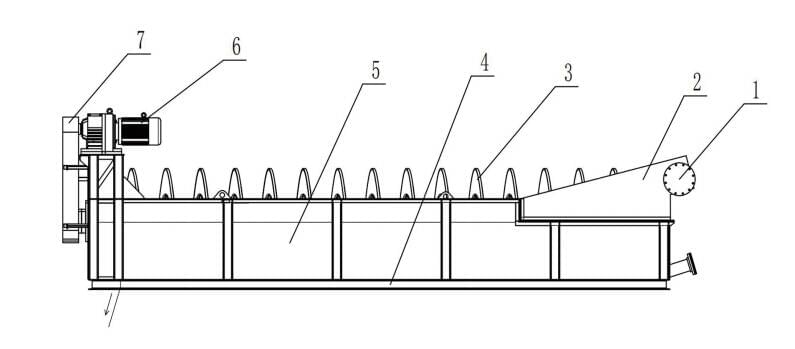

1. Overflow opening 2. Screw tail assembly 3. Screw assembly 4. Channel frame 5. Water tank 6. Motor & reducer 7. Chain shield

Features

- 1. Three functions: cleaning, dewatering and grading.

- 2. Cleaning and upward conveying at the same time.

- 3. Low water consumption.

- 4. Impellers use wear resisting plate or polyurethane material so as to reduce the running cost.

- 5. Designed according to low volume and low investment.

Screw Sand Washing Machine Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Spiral Shaft | Tank Length (mm) | Power (kw) | Overall Size (mm) |

| LX0760 | ≤10 | 20-40 | 760 | 1 | 6000 | 11 | 5700*1420*1900 |

| LX0920 | ≤10 | 30-60 | 920 | 1 | 8000 | 15 | 8710*1630*2080 |

| LX1120 | ≤10 | 40-80 | 1120 | 1 | 8000 | 18.5 | 9230*1840*2130 |

| LX1500 | ≤10 | 50-100 | 1500 | 1 | 8000 | 22 | 9620*2230*2480 |

| 2LX0920 | ≤10 | 60-120 | 920*2 | 2 | 8000 | 15*2 | 8710*2600*2080 |

| 2LX1120 | ≤10 | 80-160 | 1120*2 | 2 | 8000 | 18.5*2 | 9230*3050*2130 |

| 2LX1500 | ≤10 | 120-250 | 1500*2 | 2 | 8000 | 22*2 | 9620*3730*2480 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.