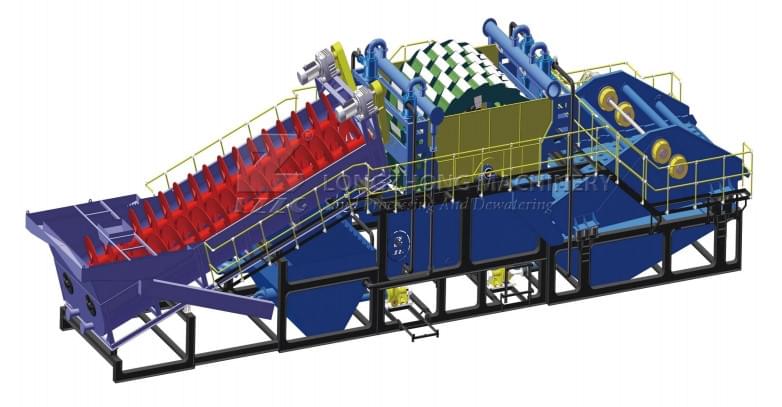

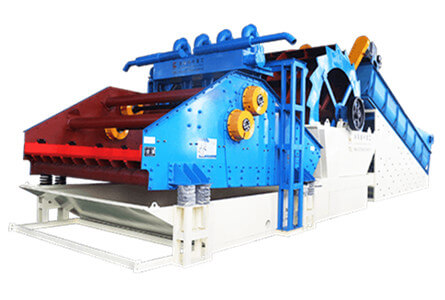

Modular Sand Wash Plant:

Modular wash plant as a representative equipment that combines multiple washing, coarse and fine materials concentrated dewatering, fine sand recycling and other functions in one equipment. It is applicable to sand and gravel plants, construction sites, hydropower dams, glass manufacturing, oil well development and other industries.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

With the shortage and non-renewable of mining resources, LZZG blockbuster launched DS series new modular sand washing plant. It is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

This machine combines wheel sand washing machine, spiral sand washing machine, dewatering screen, separator andother components into one, so that the equipment has stronger material cleaning and recovery ability.

Working Principle

Sand becomes the qualified products by the screening machinery, then flow into spiral stirrer through chute, the spiral sitter will clean, soak, break up sand ( especially direct at high mud content material), tailing waste water discharges into separating device to concentrate and grading.

Tailing and coarse ore discharges into water wheel to be cleaned and dehydrated at the same time, waste water discharges into secondary separating device to concentrate and grading, tailing and coarse ore discharges into dehydration and desliming device at the same time again.

Then the finished product which is fully dehydrated by high frequency vibrating motor will be transported into material pile by belt conveyor and for sale.

Features

- 1. Combine spiral, wheel washer in one for twice cleaning.

- 2. Efficient, energy saving, environmental protection.

- 3. Can be customized for different models, multi-layer screen.

- 4. Installation is simple, low maintenance costs.

- 5. Finished sand moisture content of less than 15%, mud content of less than 2%.

Modular Sand Wash Plant Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Spiral Diameter (mm) | Impeller Diameter (mm) | Screen Panel (mm) | Hydrocyclone(mm) | Power (kw) | Overall Size (mm) |

| DS40 | ≤10 | 20-40 | 760 | 1800X800 | 1200X2400 | 300X2 | 48.4 | 11900X5250X3880 |

| DS60 | ≤10 | 30-60 | 920 | 2600X1200 | 1500X3000 | 300X2 | 55 | 14550X5560X4150 |

| DS80 | ≤10 | 40-80 | 1120 | 3000X1600 | 1800X4200 | 300X4 | 95 | 16250X6200X3700 |

| DS100 | ≤10 | 60-100 | 920X2 | 3000X1600 | 1800X4200 | 300X4 | 110.5 | 16250X6200X3700 |

| DS150 | ≤10 | 100-150 | 1120X2 | 3600X2000 | 2400X4200 | 350X4 | 140.5 | 17450X6800X3700 |

| DS160 | ≤10 | 100-160 | 1120X2 | 3600X2400 | 3000X4800 | 300X6 | 168 | 18000X7400X4260 |

| DS200 | ≤10 | 120-200 | 1500X2 | 3600X2400 | 3000X4800 | 350X6 | 196 | 18000X7400X4600 |

| DS250 | ≤10 | 160-250 | 1500X2 | 4200X3000 | 3600X6000 | 350X6 | 214 | 18580X8000X5200 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.