Sand Washing Machine Production Line

Sand washing machine production line refers to the washing process of artificial sand (including natural sand).

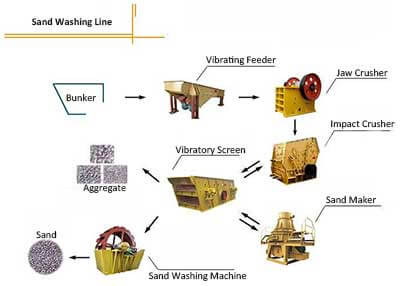

The artificial sand washing production line is composed of jaw crusher, sand making machine, sand washing machine and belt conveyor. Its process flow is: The vibrating feeder uniformly sends the stone to the jaw crusher for preliminary crushing. The preliminary crushed material is sent to the sand making machine by the belt conveyor for further crushing. The finely divided materials are conveyed to a vibrating screen for sieving. The materials that reach the standard of finished product size are sent to a sand washer for cleaning.

After cleaning, they are output by the finished product conveyor belt to become finished products. The materials that do not meet the particle size requirements are returned to the sand making machine for reprocessing from the vibrating screen, forming multiple closed-loop cycles.

Basic Introduction

Sand washing machine is a washing equipment for artificial sand (including natural sand). Sand washing machine is widely used for washing materials in sand quarry, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station and other industries.The sand washing machine also has a certain dewatering function..

Device Configuration

The artificial sand washing production line is composed of jaw crusher, sand making machine, sand washing machine and belt conveyor.

The process is as follows: The vibrating feeder uniformly sends the stone to the jaw crusher for preliminary crushing. The preliminary crushed material is sent to the sand making machine by the belt conveyor for further crushing. The finely divided materials are conveyed to a vibrating screen for sieving. The materials that reach the standard of finished product size are sent to a sand washer for cleaning.

After cleaning, they are output by the finished product conveyor belt to become finished products.The materials that do not meet the particle size requirements are returned to the sand making machine for reprocessing from the vibrating screen, forming multiple closed-loop cycles.

Working Principle

When the sand washer is working, the motor drives the impeller to rotate slowly after decelerating through the triangle belt, reducer, and gear. The sand and gravel enter the washing tank from the feeding tank, are rolled by the impeller, and are ground to each other. The gravel enters the washing tank from the feeding tank, and rolls under the drive of the impeller. Sand and stone are ground to remove impurities that cover the surface of the sand and stone and destroy the water vapor layer covering the sand particles to facilitate dehydration.

At the same time, water is added to form a powerful water stream, which timely removes impurities and foreign objects with small specific gravity and discharges them from the overflow.The clean gravel is taken away by the blades, and finally poured into the discharge trough from the rotating impeller to complete the cleaning function of the gravel.

Structural Features

(1). The structure of the sand washer is simple, and the impeller drive bearing device is isolated from water and water-receiving materials, which greatly prevents the bearing from being damaged due to water immersion, sand and pollutants.

(2). Compared with the traditional spiral sand washing machine, the sand washing machine has the following significant advantages when used for sand washing in the sand yard:

- i. The bucket sand washer has almost no wearing parts except the screen.

- ii. Long life, no maintenance required for a long time.