Sand Washing Machine With Recovery Unit:

LZZG Sand Washing Machine With Recovery Unit combined wheel sand washing machine with characteristics of sand recycling machine, making it a compact multiple function sand washing system (we also call it sand washing & recycling machine).

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

This sand washing system main parts include: XSD Wheel Sand Washer, High Frequency Dewatering Screen, High Pressure Cyclone, Cleaning Tank, Return Box, Figh Pressure Wearable Slurry Pump, Motors, etc.

The washing system has simple structure and multiple function, and is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

Working Principle

*Washing: The bucket is driven by the motor through the reducer and rotates in circle. There are many sand storage web grooves and bucket screen for sand storage and primary dewatering. When the bucket moves, sand can be put out by sand storage web groove after being cleaned in the cleaning tank and primary dewatered on the bucket screen.

*Recycling: Flowing slurry water is extracted by slurry pump, fine sand is collected by the centrifugal force of the cyclone, then fed to the polyurathane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen.

*Dewatering: Coarse sand (3-10mm) and fine sand (0.16-3mm) are fed onto polyurathane vibrating screen for dewatering.

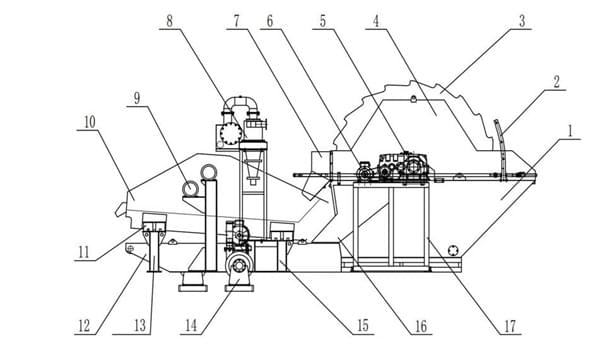

1. Water tank 2. Water sprayer 3. Impeller 4. Protect plate 5. Reducer 6. Motor 7. Discharge hopper 8. Cyclone 9. Motor 10. Dewatering screen 11. Rubber spring 12. Tank 13. Discharge part support leg 14. Slurry pump 15. Feed part support leg 16. Overflow part 17. Reducer base

Features

- 1.Higher sand quality, lower moisture content.

- 2.Recycled fine size 0.16-3mm sand, lower mud content.

- 3.Compact structure and easy installation.

- 4.High productivity and 95% of fine particles kn the material can be recycled.

- 5.Solve cleaning problem of seclimentation tank and improve economic performance at the same time.

Sand Washing Machine With Recovery Unit Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| DL40 | ≤10 | 20-40 | 1800*800 | 250*2 | 1200*2400 | 29.4 | 5800*5000*1950 |

| DL60 | ≤10 | 30-60 | 2600*1200 | 300*2 | 1500*3000 | 40 | 5800*5560*2750 |

| DL80 | ≤10 | 40-80 | 3000*1600 | 300*2 | 1800*4200 | 46.5 | 7950*6200*3700 |

| DL100 | ≤10 | 60-100 | 3000*1600 | 350*2 | 1800*4200 | 57.5 | 7950*6200*3700 |

| DL150 | ≤10 | 100-150 | 3600*2000 | 300*2 | 2400*4200 | 89.5 | 8500*6800*3700 |

| DL200 | ≤10 | 120-200 | 3600*2400 | 350*4 | 3000*4800 | 115 | 7950*7400*4100 |

| DL250 | ≤10 | 160-250 | 4200*3000 | 300*6 | 3600*6000 | 149 | 8580*8020*4860 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.