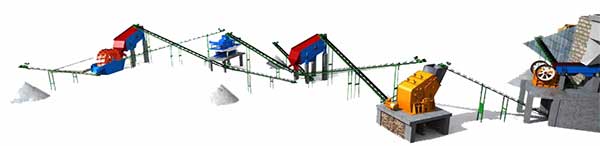

Sand Making & Washing Equipments In Sand Plant

Sand making & washing equipment mainly include: VSI sand making machine, sand washing machine, high efficiency fine impact crusher, vertical shaft impact sand making machine, fine sand recycling machine, circular vibrating screen, vibrating feeder, belt conveyor, spiral sand washing machine. The details about the machines in sand plant as bellow:

VIS Sand Making Machine

VIS Sand Making Machine is a new type of sand making machine developed on the basis of vertical shaft impact sand making machine with low consumption. This machine can realize the conversion of the two working principles of “stone hitting stone” and “stone hitting iron”. When the machine works , the material can be broken along its natural texture surface and cleavage surface, and the final finished product has a good grain shape.

Sand Washing Machine

Sand Washing Machine is a necessary machinery and equipment for domestic sand production line and has the characteristics of high cleaning degree, reasonable structure and large output. Because the transmission part of the sand washing machine is isolated from water and sand, its failure rate is much lower than the sand washing machine commonly used in the market. At the same time, the amount of sand lost during the sand washing process is small.

High Efficiency Fine Impact Crusher

High Efficiency Fine Impact Crusher has two functions of fine crushing and coarse grinding. The fine crusher machine adopts a large arc-shaped crushing chamber, and uses the principle of “stone to stone ” self-hitting crushing to repeatedly crush the material with high crushing efficiency. The crushing chamber is a screening chamber with quilting. The special crushing hammer developed by our company has the characteristics of impact resistance, wear resistance and long service life. It has achieved a revolutionary breakthrough in technology, and completely realized the low cost operation of the crusher.

Vertical Shaft Impact Sand Maker

The unique bearing installation and advanced spindle design make this machine have the characteristics of heavy load and high speed rotation. Although the industry has developed a new type of vis sand making machine, the vertical shaft impact crusher is still the main force for sand production.

Fine Sand Recycling Machine

Fine sand recovery machine is also called fine sand recovery device, which is generally used with sand washing machine. The fine sand recovery machine has two functions: dehydration and recovery. The sand washing is cleaner, and the secondary sand washing and dewatering function is added for the finished sand of the sand washing machine. Fine sand recovery rate is high, achieving 80% -90% fine sand recovery effect. This machine is designed for dewatering, demeshing and desilting of slurry materials. The most important characteristic is that it can solve the problem of fine sand loss in sand making industry.

Circular Vibrating Screen

Circular Vibrating Screen has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, ruggedness, convenient maintenance and safe use. According to the actual situation of different users, our company can customize vibrating screen with various specifications and various vibration modes.

Vibrating Feeder

The feeder produced by LZZG is a linear vibrating feeder. It has the characteristics of stable vibration, reliable work and long service life. It can continuously and uniformly feed the crusher and screen the material. The excitation force can be adjusted in the production line, and the flow can be changed and controlled at any time.

Belt Conveyor

In the production line, the belt conveyor is an important link between the production machinery and equipment. The conveyor belt moves according to the principle of friction transmission.

It has the advantages of large conveying capacity, long conveying distance, stable conveying, no relative movement between the material and the conveying belt, low noise, simple structure, convenient maintenance, low energy consumption, and standardized components, etc.