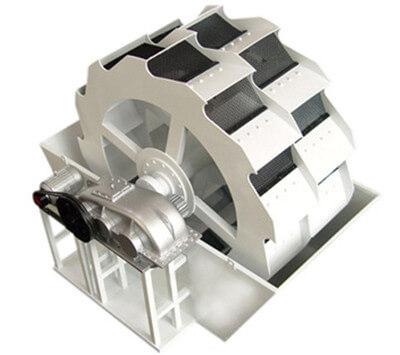

Wheel Sand Washing Machine:

Wheel Sand Washing Machine adopts wheel-like structure and equipped with sand making machine is the necessary sand washing product. It can wash stone power and residual away from the mixed sands produced by sand making machine, which can improve the sand quality mostly.

![]() Send E-mail: export@lylzzg.com

Send E-mail: export@lylzzg.com

XSD Wheel Sand washer, adopting advanced technology and taking the stone sand industry’s practical condition into consideration, is applied for washing, grading and dehydrating in sandstone factory, construction site, hydroelectric station dam, glass manufacturing and oil well development.

Working Principle

The electric motor runs slowly with the impeller after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolling with the impeller, and grinding with each other. The impurity covering (on) the sand is washing away. Adding more water at the same time, the strong water flow will take away waste and some low-weight wastes from washing launder.

The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back into the washing tank. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impeller to finish the washing task.

Features

- 1. Simple structure, the impeller rotating bearing device is separated from water and water-bearing materials to avoid bearing damage caused by water, sand and pollutants, greatly reducing the failure rate.

- 2. The loss of fine sand and stone powder is small, and the sand gradation and fineness modulus of washed buildings meet the standard requirements of crusher manufacturers.

- 3. Large processing capacity, small power consumption and long service life.

Wheel Sand Washing Machine Specifications:

| Model | Feeding Size (mm) | Capacity (t/h) | Impeller Size (mm) | Power (kw) | Overall Size (mm) |

| XSD1808 | ≤10 | 20-40 | 1800*800 | 3 | 3000*2400*1900 |

| XSD2612 | ≤10 | 30-80 | 2600*1200 | 4 | 3900*2900*2700 |

| XSD3016 | ≤10 | 60-120 | 3000*1600 | 5.5 | 4400*3300*3100 |

| XSD3620 | ≤10 | 80-160 | 3600*2000 | 7.5 | 5100*3750*3700 |

| XSD3624 | ≤10 | 100-200 | 3600*2400 | 11 | 5100*4100*3700 |

| XSD4230 | ≤10 | 160-250 | 4200*3000 | 15 | 6000*4800*4300 |

Send Inquiry

Please write down your requirement and contact details in the following form, such as Raw material type, Capacity, Feeding material size, Final product size, etc. We guarantee that your information will not be divulged to third parties and reply to you within 24 hours.